C75 range of products cross reference table equivalent grade we are mainly engaged in the special steel stainless steel tool steel alloy steel high temperature alloys heat resistant steel rod plate sheet strip coil steel wire tube pipe forgings and finished machining etc.

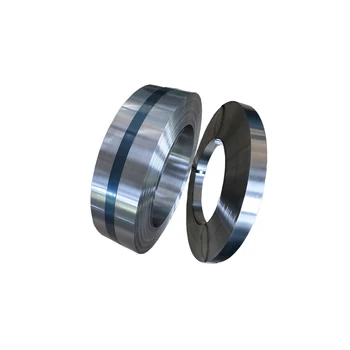

C75 steel sheet.

Used for low loaded springs and springs spring parts clock springs saws for cutting stones in the form of tapes and sheets.

Stepped shafts with flanks discs tubes slugs donuts cubes other different shapes based on oem.

C75 c75s precision steel contents brief portrait technical features chemical composition mechanical properties general thickness tolerances delivery options application examples heat treatable and spring steel whether it s for wear parts springs chain links or safety components heat treatable steels from bu precision.

75 steel c75s carbon spring steel with low hardening capacity for lightweight springs for oil hardening.

It is characterized by resistance to abrasion and high strength.

T0 1 3mm x w5 200mm x l or in coil form forging piece.

T0 5 6mm x w600 1000mm x l1000 2000mm steel strip via cold rolled.

It is a commonly used spring steel in a wide range of engineering applications.

Seventy five carbon cold rolled annealed strip steel like the 74 carbon is an excellent choice for an all purpose spring steel strip.

Od 3 219 mm with wall thickness ranging from 0 50 to 35 mm.

0 12 mm 4 mm.

Sheet steel via cold rolled.

C75 is a standard euronorm spring steel part of en10132.